Introduction

Purlin is a horizontal beam or bar used for structural support in structures, most often below the roof. Purlins are supported either by the building’s rafters or its walls. These are most commonly used in metal buildings, but in wood-frame structures, these also replace closely packed rafters. A roof’s purlins support the roof Deck’s weight. The roof deck is the wooden panel, ply board, or sheet metal which creates the roof surface. This is usually filled with some kind of weather proofing and constructed from concrete and often an insulation material.

There are many types of Purlins and are divided into groups depending on the material they are made of and the form of their shape. Different purlins are used for multiple uses including a structural wall or floor support. Purlin is necessary as there is no frame for the sheeting on the roof to rest on without it, thereby making purlins important to the roof structure.

Purlins pass roof loads to the major structural elements supporting the roof; the form and arrangement of purlins is a design factor that depends on the instance of roof loads as well as the limiting sheeting lengths to use. In the final analysis, local building codes should always be understood and implemented in the design of a concrete roof structure. Steel purlins are a substitute for conventional wood purlins. They are lightweight, stable in dimension, accurate and simple. In extreme temperature changes, they expand and contract moderately.

Steel purlin is typically made of cold-formed material, which is thin enough to get through the screws. Cold-formed steel is rendered in the desired shape by rolling or pressing thin sheets of steel in. To the producer, it is less costly than hot-rolled steel and is, therefore, simpler to deal with. Though cold-formed steel is stronger than hot-formed steel when under strain, it is more likely to crack rather than bend.

Advantages of Purlins

- Light weight : Weightless and strong.

- Capacity : Greater spanning capacity.

- Lifespan : Zinc coating to provide longer life.

- Easy Installation : They are pre-punched so welding at site is not required.

- Cost-effective : Lower maintenance costs.

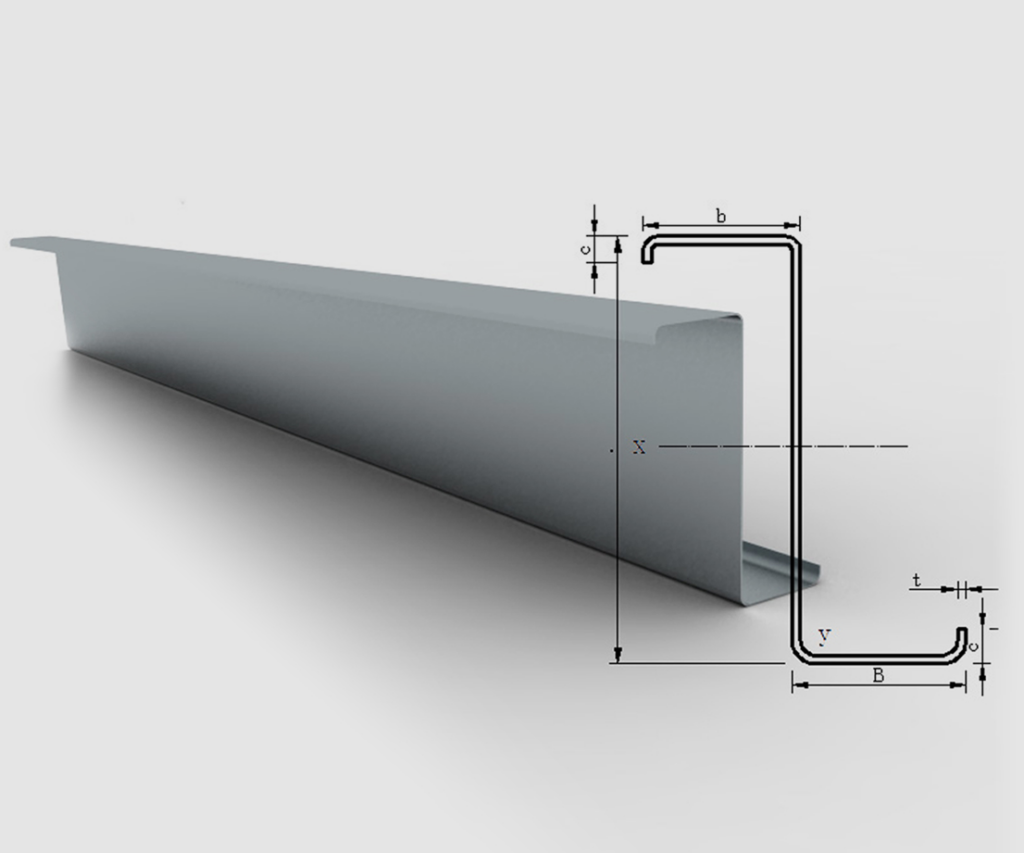

Z Purlins

Another form of Z purlin is stronger than C purlin and is mostly used together at joints and overlaps. Z purlins are horizontal beams that are built to shape a building shell structure’s roof and wall joists. They sit between the roofing sheets and the building, acting as sheet support to ensure that it is firmly attached and secure in place. Due to its relatively high flexibility and lightweight properties Z purlins are most commonly used in agricultural and industrial buildings which make them easily adapted for use in a variety of different sizes.

Read More

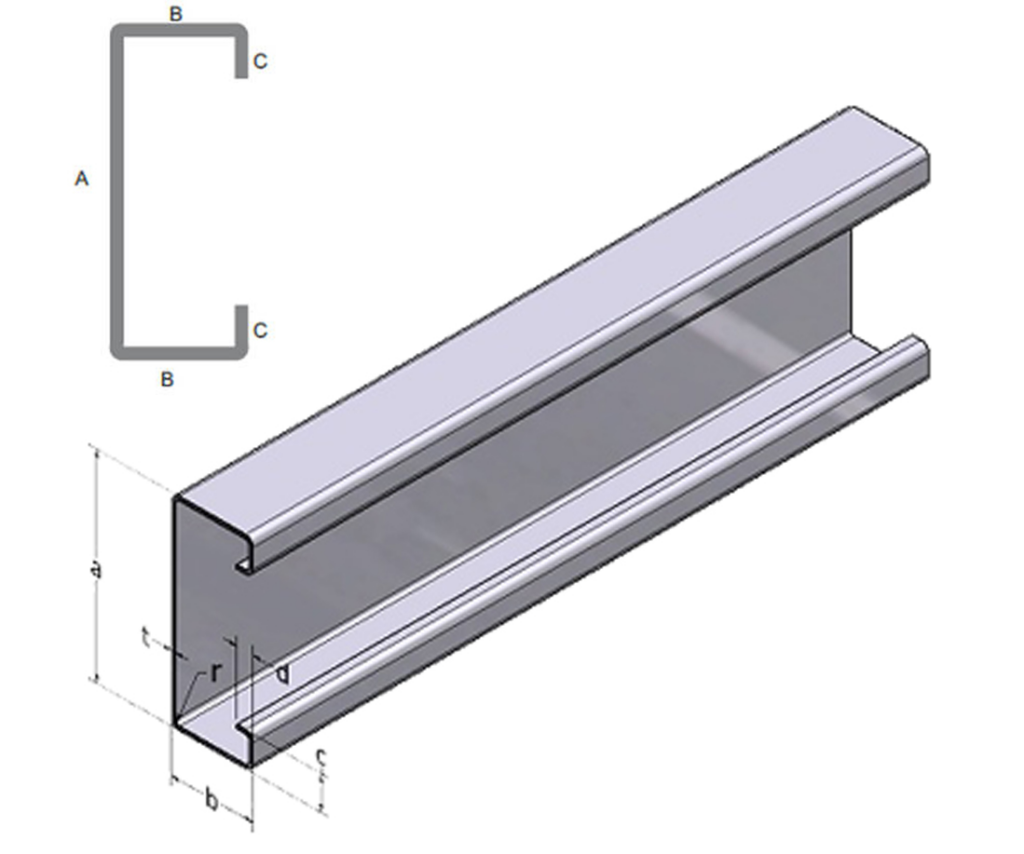

C Purlins

C purlins, as the name implies, are formed as in the C alphabet, which is primarily used to support walls and floors. C section purlins are built to shape a building shell structure’s walls and floor joists, making them also suitable for supporting the beams required for flooring. These may also use our C segment purlins with door mounting, roof clipping, window trimming, parapet rails, and side rails.

Both of our purlins in section C have similar extensions on their ends, which means they can be used in single spans. These are freestanding and secure, allowing them to be easily managed while being mounted while also offering stable support in the system.

Read More